Bridge Movement Profiles and Bearings

Pot Bearings

Technical Specifications

Pot bearings are designed to carry combinations of the vertical loads, horizontal loads, longitudinal and transversal movements and rotations. These type of bearings can carry very high loads which are over 50.000 kN A completely encased natural rubber pad is positioned in a steel pot. Under high pressure the pad behaves like a liquid. The elasticity of the rubber allows tilting movement (rotation) of the piston in the horizontal axis. Depending on whether the bearing is fixed, guided sliding or a free sliding, pot bearings accommodate vertical loads and corresponding horizontal forces as well as movements in longitudinal or transversal directions.

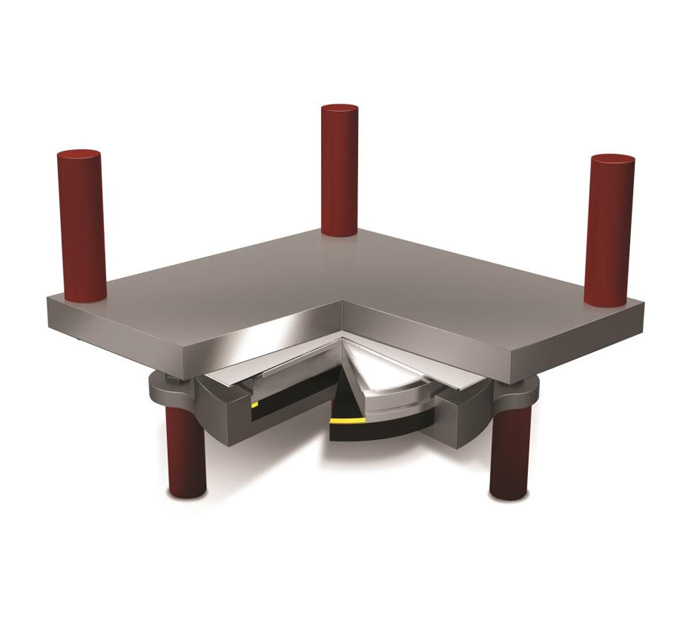

Fixed Type, These bearings consist of a pot / piston assembly within which an elastomeric disc is encapsulated and fitted with an anti-extrusion sealing device. Under load this encapsulated elastomeric disc acts in a similar manner to a nuncompress-ible confined fluid, enabling the pot and piston to rotate relative to each other. These bearings enable rotation in any direction while at the structure is constrained horizontally. The function of the pot and piston parts are for fixing and securing the bearings to the bridge structure.

Free sliding type, Identical in construction to the fixed bearings, these multi-directional devices are fitted with a virgin PTFE sheet in contact with an austenitic steelplate, enabling the bearing to slide in all directions.

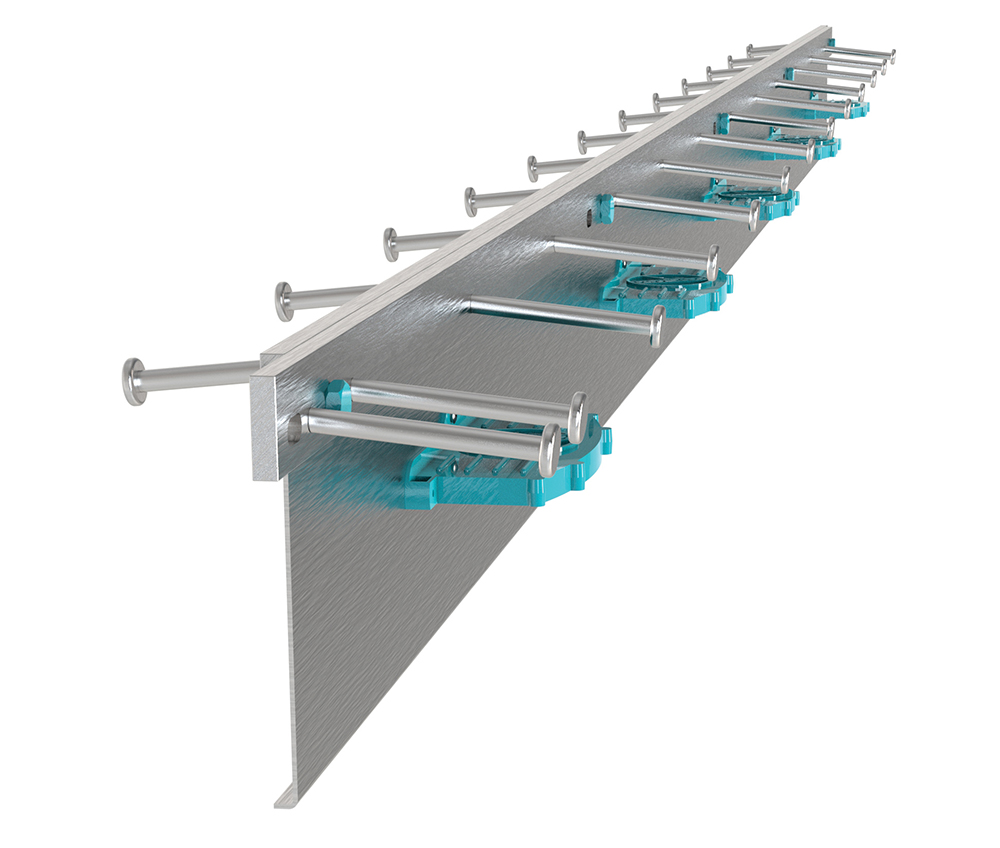

Guided Sliding type, Guided Sliding devices are identical in construction to free sliding bearings but are also fitted with one or more guides to limit the bearings movement to only one direction.

Fixed Type, These bearings consist of a pot / piston assembly within which an elastomeric disc is encapsulated and fitted with an anti-extrusion sealing device. Under load this encapsulated elastomeric disc acts in a similar manner to a nuncompress-ible confined fluid, enabling the pot and piston to rotate relative to each other. These bearings enable rotation in any direction while at the structure is constrained horizontally. The function of the pot and piston parts are for fixing and securing the bearings to the bridge structure.

Free sliding type, Identical in construction to the fixed bearings, these multi-directional devices are fitted with a virgin PTFE sheet in contact with an austenitic steelplate, enabling the bearing to slide in all directions.

Guided Sliding type, Guided Sliding devices are identical in construction to free sliding bearings but are also fitted with one or more guides to limit the bearings movement to only one direction.