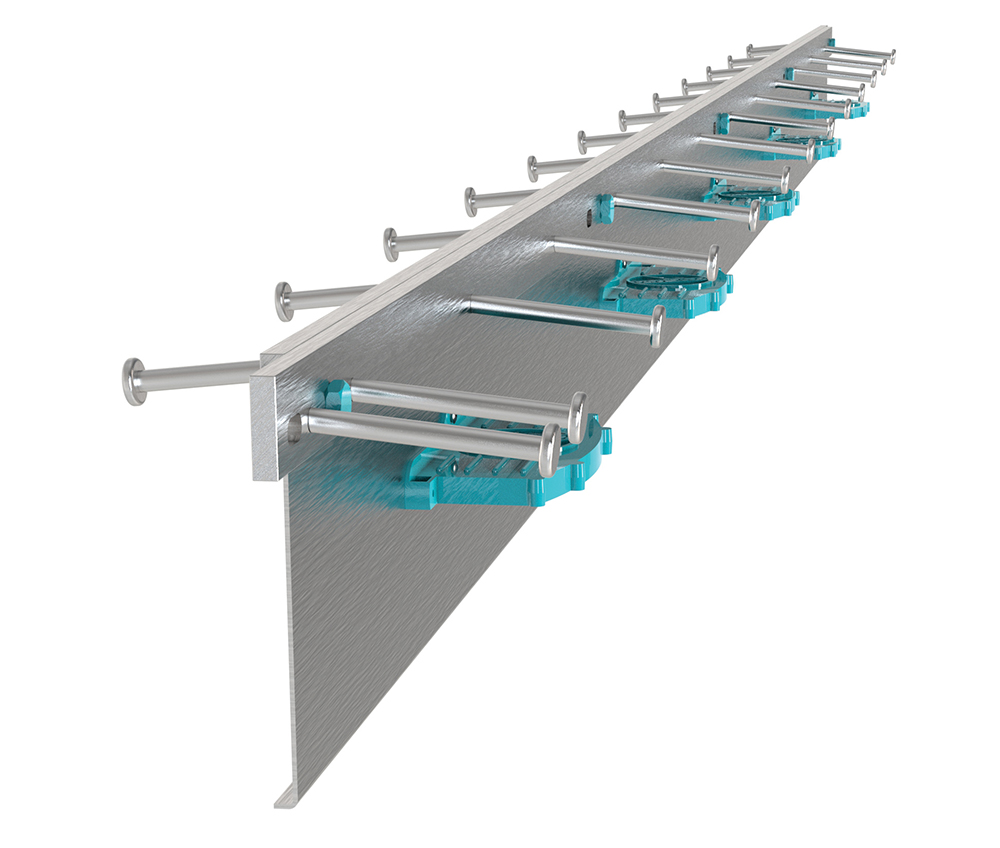

Bridge Movement Profiles and Bearings

Poly-tron Elastomeric Concrete

Technical Specifications

Poly-Tron is a fast-setting , low-viscosity , waterproof , moisture-insensitive, 100% solids, modified polyurethane elastomeric concrete material. It consists of three components which include a resin , hardener and aggregate. Its usage place is especialy in city center high trafic area where has need to repair of expansion joints.

USE

Poly-Tron is fast setting, high performance elastomeric concrete. which is especially uses repair of expansion joint edge materials. It has excellent adhesion to the concrete and steel is flexible yet tough and excellent impact resistance.

USE PLACES

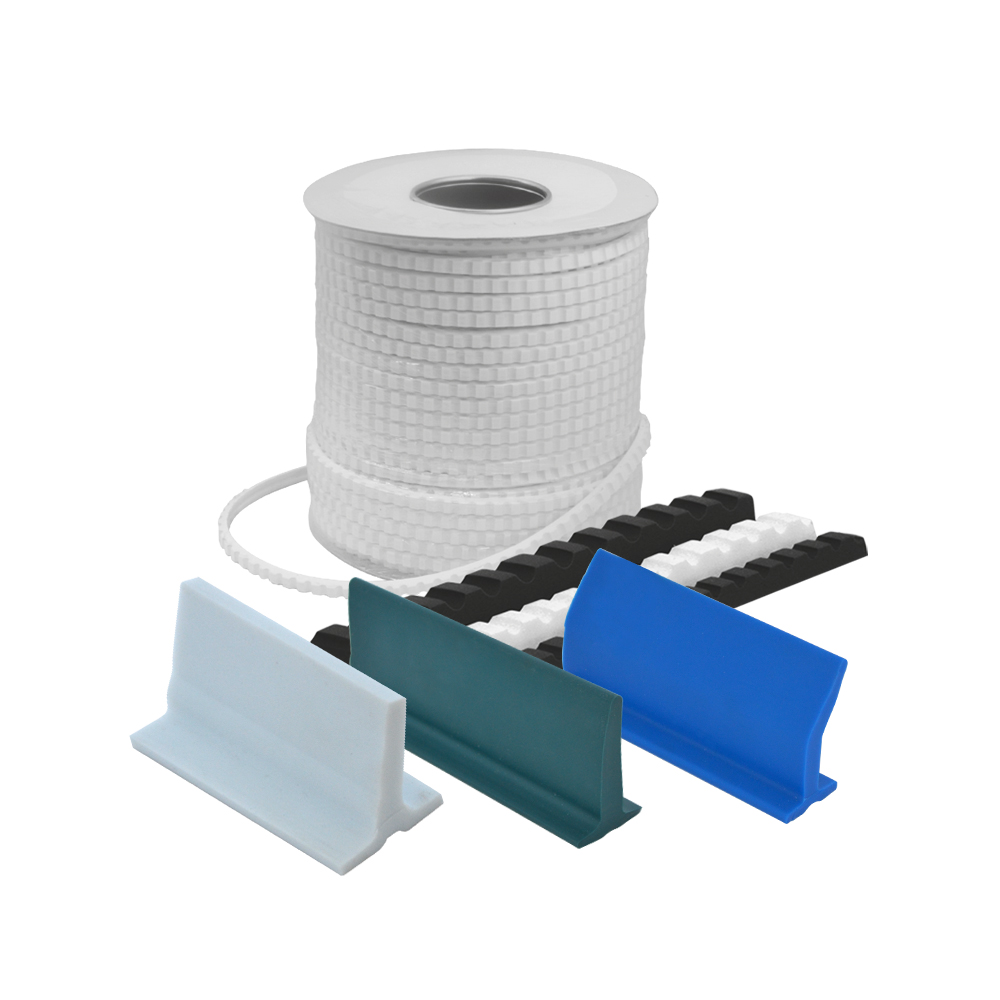

1- Expansion joints edge concrete, repair of old damaged expansion joints. Fixing new expansion joints or repair of damaged concrete of expansion joints.

2- Fixing of steel expansion joint to the structure as a flexible fixing material.

3- Like airport runway or similar places where needs fast repair.

APPLICATION

Application surface must be clean and dry (up to humidity). There wont be free materials, salt, oil, chemicals on the surface of the deck. Poly-Tron, must applicate directly on the structure (concrete slab or steel deck). Before application primer must used.

Traffic Ready Time

95º-80ºF:1-2 1/2Hours

80º-65ºF:2-3 1/2Hours

65º-45ºF:3-5 1/2 Hours

FEATURES

- Superior adhesion to various substrates

- Excellent resistance to U.V. freeze-thaw, thermal shock, impact, solvents, chemicals and moisture

- Flexible and resilient

- Easy to mix, install, and fast setting

- High quality and economical

USE

Poly-Tron is fast setting, high performance elastomeric concrete. which is especially uses repair of expansion joint edge materials. It has excellent adhesion to the concrete and steel is flexible yet tough and excellent impact resistance.

USE PLACES

1- Expansion joints edge concrete, repair of old damaged expansion joints. Fixing new expansion joints or repair of damaged concrete of expansion joints.

2- Fixing of steel expansion joint to the structure as a flexible fixing material.

3- Like airport runway or similar places where needs fast repair.

APPLICATION

Application surface must be clean and dry (up to humidity). There wont be free materials, salt, oil, chemicals on the surface of the deck. Poly-Tron, must applicate directly on the structure (concrete slab or steel deck). Before application primer must used.

Traffic Ready Time

95º-80ºF:1-2 1/2Hours

80º-65ºF:2-3 1/2Hours

65º-45ºF:3-5 1/2 Hours

FEATURES

- Superior adhesion to various substrates

- Excellent resistance to U.V. freeze-thaw, thermal shock, impact, solvents, chemicals and moisture

- Flexible and resilient

- Easy to mix, install, and fast setting

- High quality and economical